ENG - Machine Learning based Predictive Maintenance - Part 1 : The project brief

The Pharm'AI Company - Project #5

In this new article series, I’d like to discuss an example of Machine Learning usage through a project dedicated to predictive maintenance of equipment.

Some Contextual Elements

Let’s start with the basics: what is predictive maintenance?

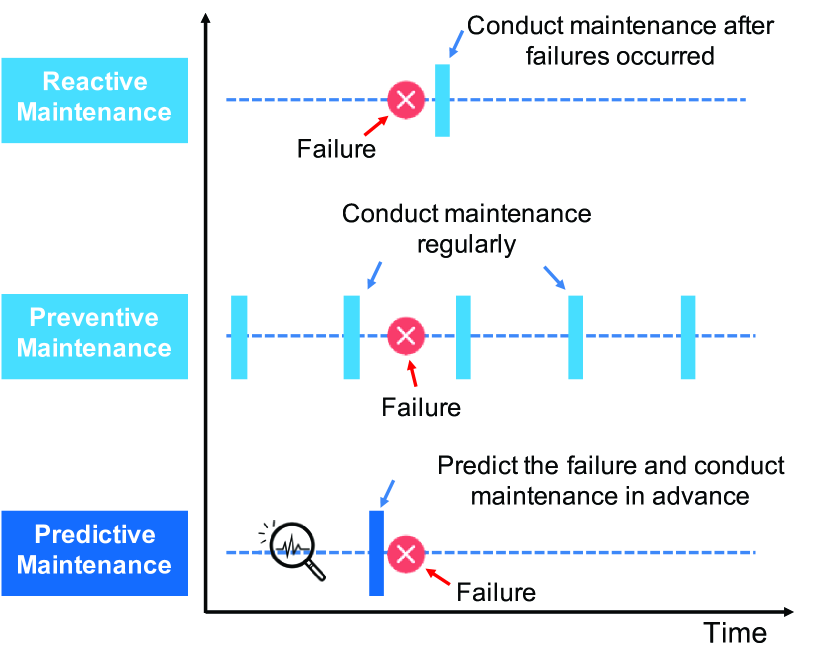

In industry, there are various types of maintenance1 :

Corrective maintenance, which addresses and fixes a malfunction that occurs on a machine. This type of maintenance is considered reactive, meaning intervention happens after a resource failure.

Preventive maintenance, which involves performing checks and/or replacing parts to anticipate and prevent breakdowns. This preventive approach can be executed in different ways:

Regularly and systematically over time, referred to as predictive or scheduled preventive maintenance.

Adaptively, based on data generated by the machine, known as conditional maintenance or preventive maintenance.

With these definitions, I think you now understand the importance of the issue.

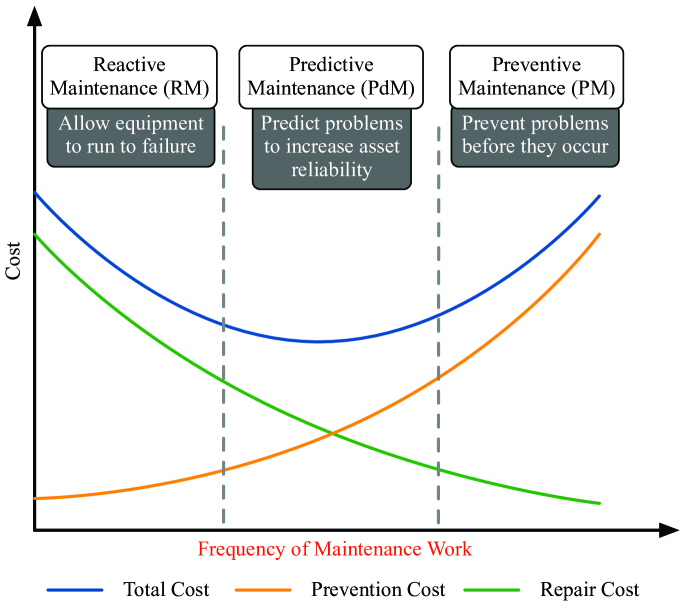

Actions that are too close together may lead to unnecessary activities, while those too far apart may increase the risk of machine breakdowns.

The advantage of implementing predictive maintenance solutions is to trigger maintenance actions based on factual data only when the risk of a breakdown is significant. The challenge, therefore, is to determine the optimal alert thresholds to minimize overall maintenance costs2.

What Data to Collect?

The Key Role of Measurement Sensors

The core of predictive maintenance lies in collecting and analyzing data generated by equipment in operation.

Manual data entry is not suited to this purpose. The volume of information to be entered is considerable, and such entries would only introduce response delays, completely contrary to the tool’s philosophy.

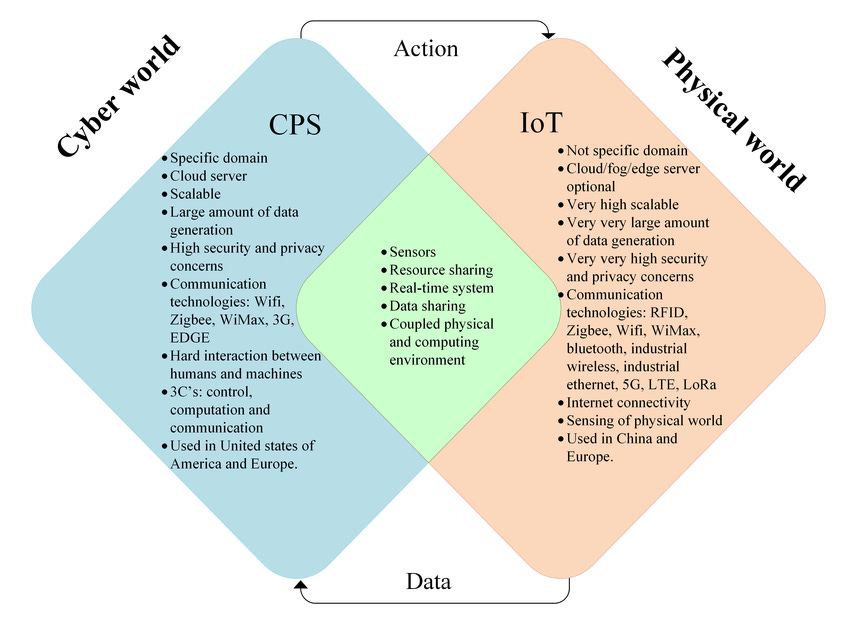

Therefore, deploying such projects requires an initial technological investment. Machines must be equipped with IIoT (Industrial Internet of Things) sensors connected to a Cyber-Physical System (CPS) that centralizes the data in a database. Generally, SCADA systems3 or tools like Data Historian4 are used for collecting, storing, and aggregating machine data5.

What Types of Sensors to Use?

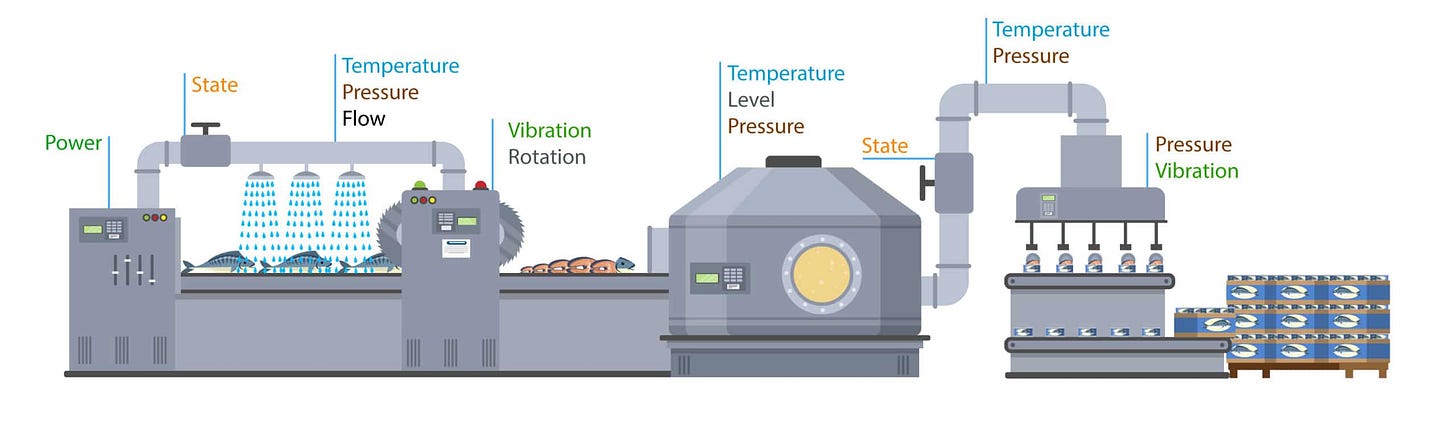

As shown in the diagram below6, there are many different types of sensors that can be used to characterize a machine's operation.

Common ones include:

Vibration and acoustic (ultrasound) sensors,

Power or electrical consumption sensors,

Temperature and pressure sensors.

However, there’s no real limit: any operational parameter from equipment can feed a Machine Learning model (e.g., rotation, torque, flow rate). Discrete events, such as states, alarms, and logs, are also relevant variables to collect and analyze.

How Often to Analyze the Data?

Once sensor data is cleaned and stored, there are two main methods for analysis:

Batch Processing: Aggregating data by cycle, day, or campaign, etc., and using a predictive Machine Learning model to make predictions based on these discontinuous data points.

Real-Time Processing as a Time Series: Using anomaly detection algorithms, which often rely on neural networks and Deep Learning, to detect deviations from normal behavior.

There’s no right or wrong solution; it depends on the project objectives, the sensors available, machine downtime costs, etc.

Benefits of Predictive Maintenance

Predictive maintenance positively impacts several business aspects:

Here are the main KPIs that measure the gains from predictive maintenance7 :

Equipment Availability and OEE (Overall Equipment Effectiveness)

Reduced unplanned downtime (fewer unexpected stops)

Reduced planned downtime (less total maintenance time)

Maintenance Costs

Reduced repair costs (fewer breakdowns and severe failures)

Optimized resource utilization (better allocation of maintenance technicians and material resources)

Quality Improvement

Well-maintained equipment is less likely to produce defects or quality variations. In the pharmaceutical industry, maintenance is regularly checked during audits and inspections.

Finally, here are a few quantified examples I found online8 :

Predictive maintenance allowed SNCF Réseau’s teams to reduce switch incidents by 30%.

AI-driven maintenance reduced costs by about 20% at Alstom.

EDF monitors its wind turbines in real-time with IoT solutions, increasing equipment availability by 1% and reducing operating and maintenance costs by 2%9.

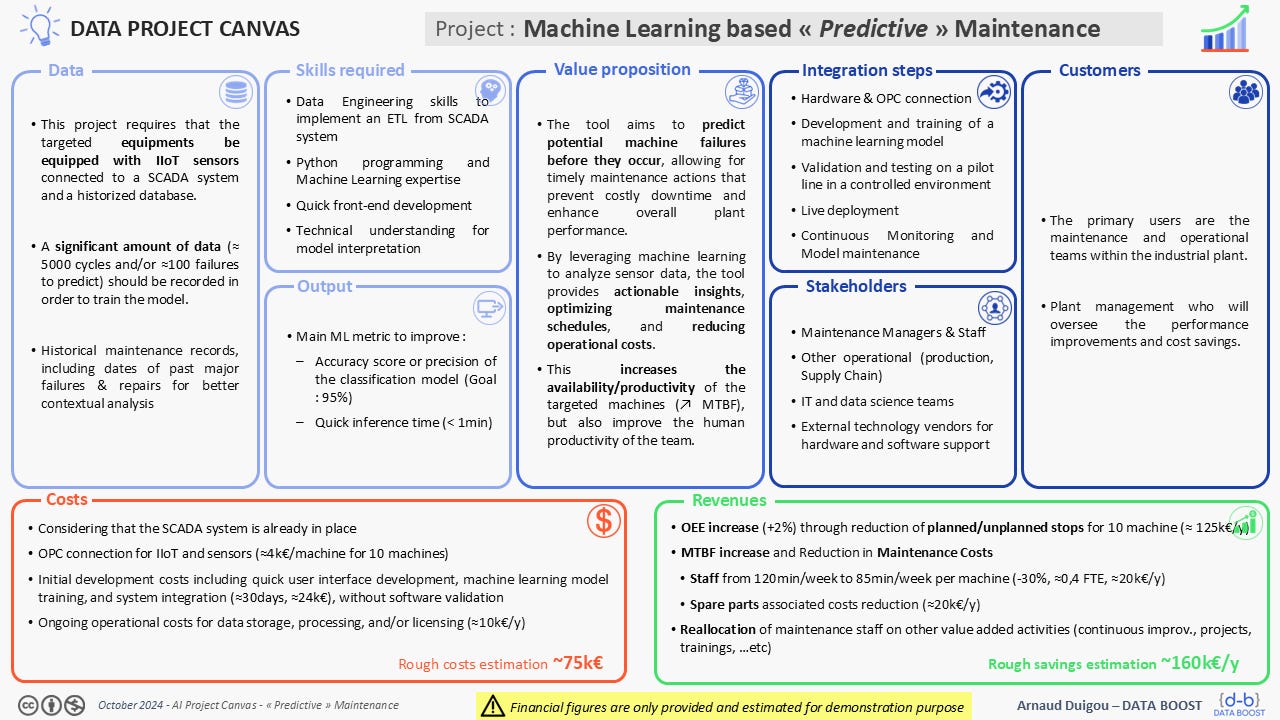

Project Charter

As always, to outline the project, I decided to formalize an AI Project Canvas10 to align as closely as possible with the industrial world. This tool specifies the project’s prerequisites, performance expectations, deployment considerations, and associated Return on Investment (ROI).

This project charter is illustrative and is based on approximations and calculation assumptions to be adjusted according to companies and their context.

An important point to consider in the ROI is the size of the fleet to cover. If several machines are equivalent, the development work will be more easily transferable from one machine to another.

Conclusion

I hope this introduction helped you understand the concept and purpose of predictive maintenance better.

In the next article, we’ll explore and analyze a maintenance dataset together.

… Waiting for that … Let’s rock with data … 🎸!